In the realm of materials science, compositionally complex materials (CCMs) have emerged as a fascinating and promising area of study. These materials, characterized by intricate combinations of multiple elements, exhibit unique and often superior properties compared to traditional alloys or ceramics. The significance of CCMs lies in their ability to unlock unprecedented functionalities, offering solutions to challenges in various industries such as aerospace, energy, and electronics. Within the broader category of compositionally complex materials, high-entropy alloys (HEAs) have garnered considerable attention. HEAs deviate from conventional alloys by containing multiple principal elements in nearly equal proportions, resulting in enhanced mechanical, thermal, and corrosion-resistant properties. Additionally, the exploration of high-entropy ceramics (HECs) has recently gained momentum, with researchers seeking to replicate the success of HEAs in the ceramic domain. These materials exhibit a novel approach to achieving exceptional hardness, thermal stability, and electrical properties.

Introduction to the Compositionally Complex Ceramics (C3) Project led by Dr. Emanuel Ionescu

Among the pioneers in the field of Compositionally Complex Ceramics (C3) is Dr. Emanuel Ionescu, a distinguished researcher renowned for his contributions to the development and understanding of advanced ceramic materials. The C3 project, under Dr. Ionescu’s leadership, aims to push the boundaries of compositionally complex ceramics, exploring novel combinations of elements to engineer materials with unparalleled properties.

Dr. Ionescu and his team are delving into the synthesis, characterization, and application of CCMs, particularly focusing on the unique challenges and opportunities presented by high-entropy ceramics. The project encompasses a multidisciplinary approach, combining expertise in materials science, chemistry, and engineering to unravel the full potential of compositionally complex ceramics.

As we embark on this exploration of the Compositionally Complex Ceramics (C3) project, we will delve into the methodologies, findings, and potential applications that arise from the innovative work led by Dr. Emanuel Ionescu and his team. Through this journey, we aim to shed light on the transformative impact that compositionally complex materials can have on various industries and pave the way for a new era of advanced materials with unprecedented capabilities

High-Entropy Materials

Exploring the complexity of high-entropy ceramics

Historical Perspective on Alloying Strategies

The evolution of materials science has witnessed a dynamic shift in alloying strategies over time. Traditionally, alloys were designed with a focus on a primary metal, supplemented by smaller amounts of secondary elements to impart specific properties. However, this conventional approach had its limitations in achieving optimal performance across multiple fronts. The historical perspective on alloying strategies underscores the need for innovative approaches that led to the development of high-entropy materials.

Overview of High-Entropy Alloys and Their Properties

High-entropy alloys (HEAs) represent a revolutionary departure from traditional alloying methodologies. Introduced in the early 21st century, HEAs are characterized by the simultaneous presence of multiple principal elements in approximately equal proportions. This departure from the conventional binary or ternary alloy systems results in unique microstructures and enhanced properties, such as exceptional strength, hardness, and resistance to wear and corrosion. The diversity of elements in HEAs contributes to a rich phase space, enabling the tuning of properties for specific applications.

Exploration of the Vast Compositional Space and Potential for Novel Materials

One of the most intriguing aspects of high-entropy materials is the vast compositional space they encompass. The exploration of this expansive territory involves the deliberate inclusion of diverse elements, offering a wide array of permutations and combinations. Researchers are delving into this uncharted territory to uncover novel materials with unprecedented properties. This exploration involves advanced computational methods, experimental synthesis techniques, and thorough characterization to identify compositions that exhibit desirable attributes for various applications, ranging from structural materials to advanced electronics.

Comparison Between High-Entropy Alloys and Compositionally Complex Ceramics

While high-entropy alloys have gained significant attention, the emerging field of compositionally complex ceramics (CCCs) introduces a parallel exploration in the ceramic domain. The comparison between high-entropy alloys and compositionally complex ceramics involves understanding the unique challenges and opportunities presented by each class of materials. Both HEAs and CCCs aim to achieve exceptional properties through the manipulation of composition, but they differ in terms of structure, processing methods, and targeted applications.

This section will delve into the distinctions between high-entropy alloys and compositionally complex ceramics, exploring the advantages and limitations of each class. Additionally, it will highlight potential synergies between the two, showcasing how a holistic understanding of compositionally complex materials can drive innovation across multiple material systems. Through this comparative analysis, we aim to provide insights into the diverse landscape of high-entropy materials, paving the way for future advancements in the field of advanced materials science

Compositionally Complex Ceramics

Exploring the complexity of high-entropy ceramics

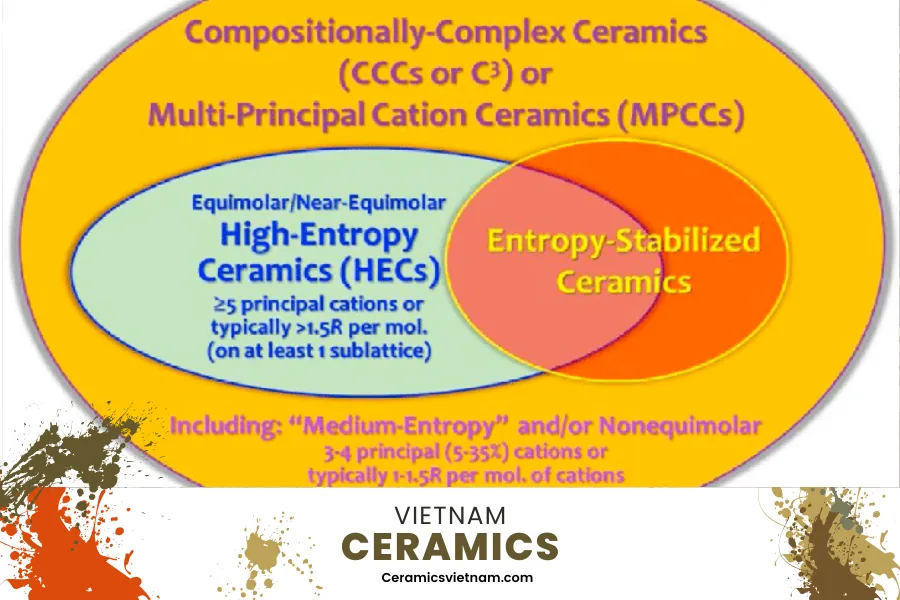

Definition and Characteristics of High-Entropy Non-metallic Inorganic Compounds

The term “high-entropy” is conventionally associated with metallic alloys, but recent advancements have extended the concept to non-metallic inorganic compounds, leading to the emergence of high-entropy ceramics (HECs). These materials challenge traditional ceramic design by incorporating a multitude of elements in significant proportions. High-entropy non-metallic inorganic compounds exhibit a departure from the conventional binary or ternary compositions seen in traditional ceramics. The key characteristics include an intricate mix of elements, resulting in a complex and often disordered atomic arrangement, offering unique properties not attainable through simpler compositions.

Explanation of Compositionally Complex Ceramics and Their Crystal Phase Composition

Compositionally complex ceramics (CCCs) represent a subset of high-entropy ceramics that delve into the intricate interplay of elements within the ceramic matrix. The crystal phase composition of CCCs is marked by the coexistence of multiple phases, often amorphous or nanocrystalline, contributing to the overall complexity and uniqueness of the material. Unlike traditional ceramics with well-defined crystal structures, CCCs present a challenge in characterizing their phase composition due to the disorder introduced by the high-entropy nature of their constituents. Understanding and controlling this crystal phase composition is essential for tailoring the properties of CCCs for specific applications.

Entropic Stabilization and Its Role in the Stability of Compositionally Complex Ceramics

Entropic stabilization plays a crucial role in the stability of compositionally complex ceramics. In traditional ceramics, stability is primarily governed by thermodynamic considerations, focusing on minimizing the free energy of the material. However, in CCCs, the high configurational entropy resulting from the disorderly arrangement of multiple elements introduces a new dimension to stabilization. This entropic effect can contribute to the suppression of phase transformations, enhancing the stability of CCCs at elevated temperatures. Investigating and harnessing entropic stabilization mechanisms are key aspects of advancing the understanding and application of compositionally complex ceramics.

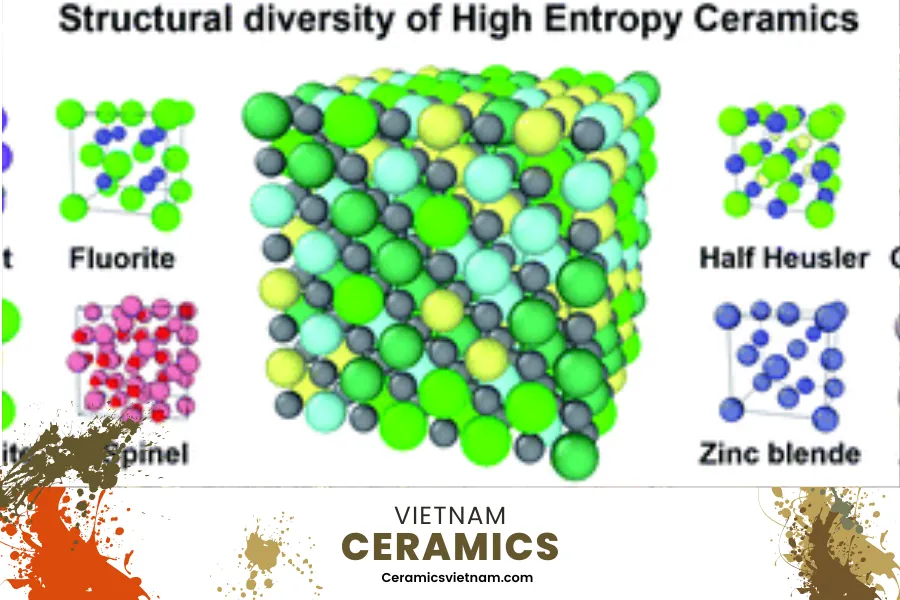

Structural Diversity and Properties of Compositionally Complex Ceramics

The structural diversity of compositionally complex ceramics is a hallmark of their unique nature. The incorporation of multiple elements in various proportions results in a wide range of potential crystal structures and microstructures. This diversity is reflected in the properties exhibited by CCCs, including enhanced mechanical strength, thermal stability, and resistance to environmental degradation. The structural complexity also enables the tuning of properties for specific applications, opening up new avenues for advancements in areas such as electronics, catalysis, and energy storage.

This section will delve into the intricate world of compositionally complex ceramics, exploring their definition, crystal phase composition, entropic stabilization mechanisms, and the diverse properties arising from their unique structural features. By unraveling the complexities of these materials, we aim to contribute to the growing body of knowledge surrounding high-entropy non-metallic inorganic compounds and inspire further research in this innovative field

Design of Compositionally Complex Ceramics

Exploring the complexity of high-entropy ceramics

Challenges in Developing New Materials with a Vast Compositional Space

The vast compositional space inherent in compositionally complex ceramics (CCCs) presents both exciting opportunities and daunting challenges. One of the primary challenges is navigating and comprehensively exploring this expansive design space. Traditional trial-and-error experimental approaches become impractical due to the sheer number of possible compositions. Additionally, the interplay of numerous elements increases the complexity of predicting the resulting material properties. Balancing the need for innovation with the practical challenges of exploring the vast compositional space is a critical hurdle in the design of CCCs.

In Silico Approaches for Screening Stable Compositions

In response to the challenges posed by the vast compositional space, researchers are increasingly turning to in silico approaches for efficient screening of stable compositions. Computational methods, such as density functional theory (DFT) and molecular dynamics simulations, offer a powerful means to predict material behavior without the need for extensive experimental trials. In silico screening enables researchers to identify promising compositions with desirable properties, significantly reducing the time and resources required for material development. This approach enhances the efficiency of the design process, allowing for targeted exploration of the vast compositional landscape.

Use of Descriptors and Quantum-Mechanical Methods in Computational Screening

To streamline the in silico screening process, researchers rely on descriptors and quantum-mechanical methods. Descriptors are parameters that quantify specific aspects of a material’s structure or properties, aiding in the identification of relevant compositions. Quantum-mechanical methods, such as DFT, provide a detailed understanding of the electronic and structural characteristics of materials. The integration of these tools enables researchers to develop predictive models that correlate composition with desired properties. This computational screening approach, driven by advanced techniques, facilitates the identification of compositionally complex ceramic formulations with tailored properties.

Early-Stage Developments in the Design of Compositionally Complex Ceramics

As researchers embark on the design of compositionally complex ceramics, early-stage developments showcase the potential of this innovative field. Initial successes include the synthesis of novel CCCs with enhanced mechanical strength, thermal stability, and resistance to environmental factors. Researchers are exploring diverse combinations of elements to achieve specific functionalities, ranging from advanced structural materials to high-performance catalysts. Collaborations between experimentalists and computational scientists are becoming increasingly common, fostering a synergistic approach to material design. These early-stage developments lay the foundation for future breakthroughs in the field of compositionally complex ceramics.

This section will delve into the ongoing efforts and methodologies in the design of compositionally complex ceramics, highlighting the challenges faced, the role of computational screening, and the promising early-stage developments shaping the landscape of high-entropy non-metallic inorganic compounds. By navigating these challenges and leveraging advanced computational tools, researchers aim to unlock the full potential of CCCs, paving the way for a new era of advanced ceramic materials

Synthetic Approaches

Overview of Current Knowledge on Oxidic and Non-Oxidic Ceramics

Before delving into the specific challenges and synthetic approaches for high-entropy ceramics (HECs), it’s crucial to establish a foundation by understanding the current knowledge surrounding oxidic and non-oxidic ceramics. Oxidic ceramics, often composed of metal oxides, and non-oxidic ceramics, such as nitrides and carbides, have distinct properties and applications. These traditional ceramics form the basis of our understanding, providing a context for exploring the innovative realm of high-entropy ceramics.

Challenges in Synthesizing High-Entropy Ceramics, Particularly Nitrides and Carbonitrides

The synthesis of high-entropy ceramics, especially nitrides and carbonitrides, presents a unique set of challenges. Unlike their metallic counterparts, these ceramic systems often require high temperatures and controlled atmospheres for synthesis, posing difficulties in achieving uniform compositions and preventing phase segregation. The incorporation of multiple elements in these non-metallic compounds adds an extra layer of complexity. Overcoming these challenges is essential for realizing the full potential of high-entropy ceramics in applications ranging from structural materials to advanced electronic devices.

Focus on the Work of the C3 Group and Their Low-Temperature Molecular Preparative Routes

Addressing the challenges in synthesizing high-entropy ceramics, the Compositionally Complex Ceramics (C3) group, led by Dr. Emanuel Ionescu, has made significant strides in developing low-temperature molecular preparative routes. This innovative approach involves the use of molecular precursors to create high-entropy ceramics at lower temperatures than traditional methods. The C3 group’s work focuses on tailoring molecular precursors to achieve desired compositions and exploiting precursor chemistry to control the final ceramic’s properties. These low-temperature routes not only overcome challenges associated with high-temperature synthesis but also enable the incorporation of a wider range of elements into the final ceramic structure.

Structural Characterization and the Role of Entropic Stabilization in Experimental Perspectives

The experimental perspectives on high-entropy ceramics include rigorous structural characterization to understand the complex arrangements of elements within the material. Techniques such as X-ray diffraction, transmission electron microscopy, and spectroscopy play crucial roles in unveiling the crystal structures and microstructures of these ceramics. In addition, the role of entropic stabilization in experimental perspectives is a key focus. Researchers aim to elucidate how the disorder introduced by multiple elements contributes to the stability of the material, influencing its phase transformations and overall performance. Understanding these aspects is pivotal for optimizing synthetic routes and tailoring properties for specific applications.

This section will provide a comprehensive overview of the current knowledge on oxidic and non-oxidic ceramics, the challenges specific to high-entropy ceramics, the innovative low-temperature molecular preparative routes pioneered by the C3 group, and the experimental perspectives on structural characterization and entropic stabilization. By addressing these aspects, researchers aim to unlock the full synthetic potential of high-entropy ceramics and pave the way for their widespread application in diverse technological fields

Properties and Applications

Examination of Physical and Chemical Properties of Multicomponent Non-Oxidic Ceramic Samples

To fully appreciate the potential of high-entropy ceramics (HECs), it is crucial to conduct a detailed examination of their physical and chemical properties. Multicomponent non-oxidic ceramic samples, synthesized with innovative low-temperature molecular preparative routes, exhibit a diverse range of properties. These properties include but are not limited to mechanical strength, hardness, thermal stability, electrical conductivity, and resistance to wear and corrosion. Understanding these intrinsic characteristics is essential for tailoring HECs to specific applications across various industries.

Insight into the Role of Configurational Entropy in Driving Specific Properties

Configurational entropy, a key feature of high-entropy materials, plays a pivotal role in influencing specific properties of multicomponent non-oxidic ceramics. The disorderly arrangement of multiple elements within the ceramic matrix contributes to enhanced configurational entropy, impacting the material’s behavior. This section will provide insight into how configurational entropy influences properties such as phase stability, lattice distortion, and defect formation. Understanding the interplay between configurational entropy and material properties is essential for harnessing the full potential of HECs.

Ability to Control and Fine-Tune Properties for Potential Applications

One of the remarkable aspects of high-entropy ceramics is the ability to control and fine-tune their properties for specific applications. Researchers can manipulate the composition, processing conditions, and precursor chemistry to tailor the properties of HECs according to the requirements of diverse technological fields. This adaptability makes high-entropy ceramics highly versatile, opening up possibilities for applications in structural materials, electronic devices, catalysis, and more. This section will explore the methods and strategies employed to control and fine-tune the properties of HECs, showcasing their potential for customization.

Discussion on Promising Technological Fields Impacted by Novel Synthetic Routes

The novel synthetic routes developed by the C3 group and similar research endeavors have the potential to impact various technological fields significantly. This section will engage in a discussion on the promising applications of high-entropy ceramics in fields such as aerospace, energy storage, electronics, and catalysis. By highlighting the unique properties and capabilities of HECs, we aim to shed light on how these materials can address specific challenges in each technological domain. The discussion will emphasize the transformative impact of novel synthetic routes on the development of advanced materials with enhanced performance and capabilities.

In conclusion, this section will delve into the properties and applications of high-entropy ceramics, focusing on the examination of physical and chemical properties, the role of configurational entropy, the ability to control and fine-tune properties, and a discussion on promising technological fields impacted by novel synthetic routes. By exploring these aspects, we aim to provide a comprehensive understanding of the potential of high-entropy ceramics and their role in advancing technology across diverse industries

Future Perspectives

Exploring the complexity of high-entropy ceramics

Potential Applications in Energy Conversion, Storage, Thermoelectrics, Catalysis, Optics, and Photonics

The future perspectives of high-entropy ceramics (HECs) hold immense promise across a spectrum of applications. In the realm of energy, HECs are anticipated to play a crucial role in energy conversion and storage technologies. Their unique properties, including enhanced thermal stability and electrical conductivity, make them ideal candidates for advanced battery materials and components. Additionally, HECs may find applications in thermoelectrics, where the ability to efficiently convert heat into electricity is paramount. The versatility of HECs extends to catalysis, optics, and photonics, offering opportunities for the development of high-performance catalysts and advanced materials for optical and photonic devices. This section will delve into the potential applications of HECs in these key areas and discuss how their distinct properties can drive innovations in energy-related technologies.

Relevance in Addressing Raw Material Fluctuations and Recycling Purposes

The inherent diversity and compositional flexibility of high-entropy ceramics position them as potential solutions to address challenges related to raw material fluctuations and recycling. By utilizing a wide range of elements, HECs can mitigate the impact of fluctuations in the availability of specific raw materials. Moreover, their unique compositions may enhance the recyclability of materials, reducing the dependence on scarce resources. This section will explore the role of HECs in sustainable materials development, emphasizing their potential to contribute to a more resilient and environmentally friendly approach to material sourcing and recycling.

Anticipated Advancements and Contributions to Materials Science and Technology

The future of high-entropy ceramics holds exciting prospects for advancements in materials science and technology. Anticipated developments include the discovery of new compositions with tailored properties, breakthroughs in processing techniques, and a deeper understanding of the fundamental principles governing the behavior of high-entropy materials. Researchers envision the integration of HECs into diverse technological applications, driven by a combination of computational design, innovative synthesis methods, and targeted property optimization. This section will provide insights into the anticipated advancements and contributions that HECs are poised to make, shaping the landscape of materials science and technology in the years to come.

In conclusion, the future perspectives of high-entropy ceramics are multifaceted, spanning potential applications in energy-related technologies, addressing raw material challenges, and contributing to the advancement of materials science and technology. By exploring these future trajectories, we aim to underscore the transformative impact that high-entropy ceramics may have on various industries and their role in shaping a more sustainable and technologically advanced future

Leave a reply