In the art world, pottery has long been a unique and refined form of creativity. However, you don’t need to be a professional artist or have a spacious studio to create unique ceramic pieces. So, let’s explore together with CeramicVietNam how to make pottery at home through simple steps!

Introduction to ceramics

How to make pottery at home in 5 simple and detailed steps

Ceramics are a type of utensil widely used in construction, palaces, even water channels, and household items, with a history spanning over 25,000 years. This usage traces back to the time when humans discovered fire, left caves, and stone shelters, and started building settlements. There are two main methods of making ceramics mentioned: traditional ceramics and non-fired ceramics.

Composition of Ceramics: Pottery is typically crafted by taking a mixture of clay, soil elements, powder, and water, shaping them into desired forms. Once shaped, the pottery undergoes high-temperature firing in a kiln. Usually, ceramics are coated with decorative substances, waterproofing, similar to a coating called glaze.

Pottery is both a creative and ancient art form that has captivated human expression for centuries. This craft, which involves shaping and molding clay into functional or decorative items, holds a rich history dating back thousands of years. However, what makes it truly fascinating is its enduring relevance, allowing individuals to tap into their artistic instincts and produce unique pieces even today.

The emphasis lies in the accessibility of pottery creation at home. In the past, pottery might have been associated with specialized studios or professional artists, but now, with the right guidance and resources, anyone can engage in the pottery-making process within the comfort of their own home. This accessibility breaks down barriers, encouraging individuals from various backgrounds and skill levels to explore their creativity through the art of pottery.

To facilitate this creative journey, this guide provides an introduction to the 5-step process for making pottery at home. These steps are designed to be simple yet detailed, ensuring that even beginners can embark on this artistic endeavor with confidence. As we delve into each stage, we will discover the intricacies of preparing materials, designing, sculpting, painting, decorating, glazing, and firing pottery, all within the familiar and welcoming environment of one’s home

Preparing pottery materials

There are various ways to make pottery at home depending on the type of product you desire. In general, one of the basic methods for making pottery at home involves preparing the following tools and materials:

- Clay mixer: Used to mix clay and water into a smooth mixture.

- Workspace: Provides a working space for shaping and finishing ceramic products.

- Pottery clay: Choose the appropriate type of clay for your intended use, including regular clay, porcelain clay, or polished pottery clay.

- Shaping tools: Include molds, clay hammers, clay saws, and other shaping tools to create the desired shape for the ceramic product.

- Brushes and brushes: Used for painting and decorating pottery. Select brushes and brushes that match the type of paint and technique used.

- Paints and decorative materials: To add color and patterns to ceramic products, you need to prepare suitable ceramic paints and decorative materials.

- Pottery kiln: To fire the ceramic products into ceramics, you need a pottery kiln with the appropriate temperature and firing mode.

Pottery making process

Step 1: Clay preparation – choosing and processing clay

Before starting pottery at home, you need to determine the type of clay that suits your purpose and technique. There are various types of clay, and as a result, the methods for making pottery at home differ, including regular clay, porcelain clay, and polished pottery clay. Each type of clay has its own characteristics and applications, so research and choose the clay that suits your project.

To make pottery at home, the first step is to refine the clay. This process involves watering and using a thin wire tool to knead the clay.

Afterward, impurities are removed, and the clay is kneaded thoroughly to form large piles. The clay is then repeatedly cut and stacked to achieve the desired smoothness and pliability. This stage is called “clay wedging” and is the crucial first step in various methods of making pottery at home.

Step 2: Design and sculpting

Before beginning the clay sculpting process, brainstorm and create a specific design for your product. You can sketch or model your ideas on paper or use clay to create a prototype. This helps you visualize the concept in the process of making pottery at home and identify the necessary details before getting started.

Step 3: Painting and decorating

How to make pottery at home in 5 simple and detailed steps

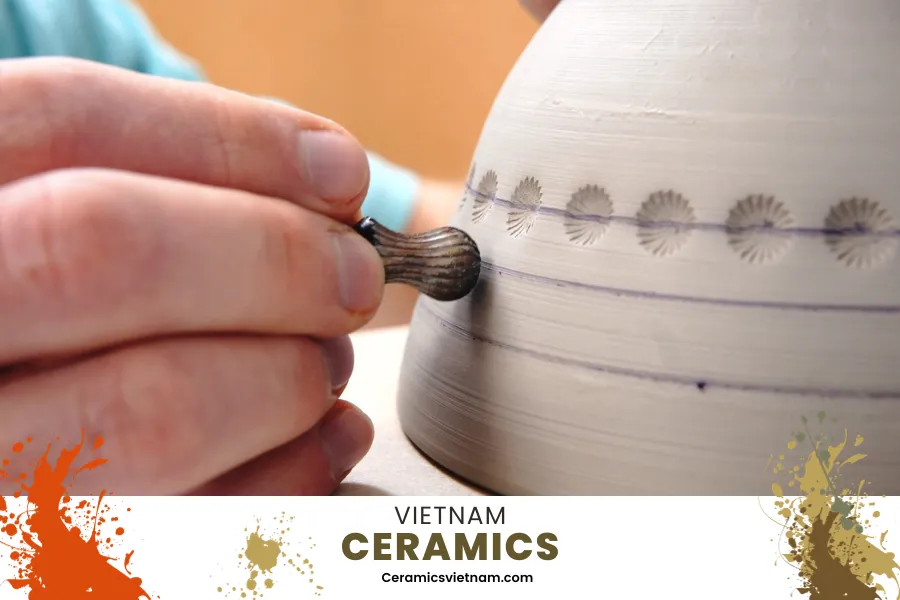

The technique of painting and decorating pottery plays a crucial role in bringing beauty and refinement to ceramic products. By using various paint colors and different techniques, you can create unique patterns, designs, and effects on the surface of the pottery.

- Direct Painting: Use paint and suitable tools to apply color directly to the surface of the pottery. You can use brushes, paint pens, or other special tools to create patterns, designs, and color details.

- Compression Technique: Apply a thin layer of paint and compress it tightly onto the surface of the pottery before firing. This technique creates a multi-tone color effect and a unique combination of different color layers.

Step 4: Glazing

For small-sized ceramic products, a common method to protect and strengthen the surface is by dipping them into glaze. This glazing process helps create a smooth and even protective glaze layer across the entire product.

However, for larger ceramic products, the pouring or spraying glazing method is often employed. This requires technique and experience to ensure an even and non-dripping glaze layer. This process contributes to forming a resilient protective glaze layer while enhancing the aesthetic appeal of the product.

The firing and glazing process are crucial steps in perfecting ceramic products, playing a significant role in preserving and safeguarding the products for durability and maintaining the beauty of the ceramics in the long run.

Step 5: Firing the pottery

The pottery firing process is a crucial step in transforming the product from a soft and malleable clay state into a sturdy ceramic. During the firing process, the ceramic product goes through various temperature stages to eliminate water, burn off organic materials, and transform into a permanently unalterable material.

Leave a reply