In the ever-evolving landscape of medical technology, Original Equipment Manufacturers (OEMs) are constantly seeking innovative materials to enhance the performance and longevity of medical devices. One such material gaining prominence is ceramic materials. This article delves into the crucial factors OEMs must consider when incorporating ceramic materials into their medical devices.

Characteristics of ceramic materials

Electrical properties

Ceramic materials, known for their diverse applications, exhibit distinctive electrical properties that set them apart in the realm of materials science. This discussion delves into the specific characteristics related to the electrical behavior of ceramic materials, focusing on their role in electrical insulation and the intriguing aspect of conductivity, including the emergence of semiconductor ceramics.

At the heart of ceramic materials lies a fundamental characteristic – electrical insulation. Unlike metals and some polymers, ceramic materials are inherently non-conductive. This property makes them invaluable in applications where preventing the flow of electricity is essential. From high-voltage insulators in power transmission lines to the insulation of electronic components, ceramic materials provide a reliable barrier, ensuring the safe containment and isolation of electrical currents.

While ceramic materials, in general, are renowned for their electrical non-conductivity, the landscape shifts with the introduction of advanced ceramics. This subset challenges the conventional wisdom by exhibiting a degree of conductivity. Among these advanced ceramics, there exists a fascinating category – semiconductor ceramics.

- Temperature-dependent conductivity: Semiconductor ceramic materials showcase a unique response to temperature variations. Depending on the temperature, these ceramics can transition from being insulators to conductors, offering a dynamic range of electrical behavior. This temperature-dependent conductivity is a pivotal aspect of their utility in various applications.

- Voltage-driven conductivity: Another intriguing characteristic is the ability of semiconductor ceramics to conduct electricity under specific voltage conditions. By manipulating the applied voltage level, it’s possible to control and modulate the conductivity of these ceramics. This opens avenues for tailored electrical responses in electronic devices.

Physical properties

Ceramic materials stand out in the world of materials science due to their unique physical properties. This exploration focuses on key characteristics, emphasizing the exceptional hardness, stiffness, impact resistance, and specific gravity that define advanced ceramics.

The hallmark of advanced ceramics lies in their unparalleled hardness. A standout example is alumina, boasting a hardness nearly three times that of stainless steel. This exceptional hardness not only ensures longevity but also opens doors to applications demanding robust and wear-resistant materials. In industries ranging from manufacturing to aerospace, the superior hardness of ceramic materials provides a distinct advantage in durability and performance.

Ceramic materials exhibit a high degree of stiffness, a property measured by assessing elasticity after applying force. This inflexibility makes ceramic materials ideal for applications where deformation avoidance is critical. Whether in precision engineering components or structural elements, the stiffness of ceramics contributes to the integrity and reliability of the final product, ensuring it maintains its form under varying pressures and forces.

Historically, technical ceramics faced challenges in impact resistance, with a tendency towards brittleness. However, the emergence of stabilized Zirconia has transformed this landscape. Stabilized Zirconia offers substantial improvements in resistance to reaching the breaking point, enhancing the overall durability of ceramic materials. This breakthrough opens new avenues for applications in high-stress environments, where impact resistance is paramount.

Ceramic materials present a paradigm shift in weight dynamics due to their lower density compared to high-strength metals. In a given volume, many ceramics can reduce weight to half that of metal. This reduction in specific gravity not only makes ceramics advantageous in weight-sensitive applications, such as aerospace components but also contributes to improved fuel efficiency and overall system performance.

Chemical properties

The chemical properties of ceramic materials stand as a testament to their resilience and adaptability. Advanced ceramics, in particular, exhibit a remarkable level of chemical stability, making them indispensable in environments fraught with corrosive challenges. This exploration sheds light on the chemical characteristics of ceramics, emphasizing their resistance to corrosive agents such as hydrochloric acid, sulfuric acid, nitric acid, and sodium hydroxide.

Characteristics of ceramic materials

At the core of the chemical properties of ceramic materials lies their high level of chemical stability. This stability is a result of the unique composition and structure of ceramic materials, making them resistant to the detrimental effects of various corrosive agents. In environments where chemical degradation is a constant threat, the chemical stability of ceramics ensures long-term reliability and performance.

Advanced ceramic materials exhibit an impressive resistance to a spectrum of corrosive agents. This includes but is not limited to hydrochloric acid, sulfuric acid, nitric acid, and sodium hydroxide. This resistance is a game-changer in industries where exposure to such corrosive substances is unavoidable. From chemical processing plants to laboratory equipment, ceramics provide a robust defense against the corrosive effects of these agents.

Thermal properties

Ceramic materials exhibit remarkable thermal properties that distinguish them in various industrial applications. This discussion delves into three key thermal characteristics of ceramic materials: heat resistance, thermal expansion, and thermal conductivity, shedding light on how these properties contribute to the resilience and functionality of ceramics in diverse settings.

A defining characteristic of ceramics is their exceptional heat resistance. Across various types, ceramic materials showcase an ability to withstand high temperatures. Take alumina, for instance, which can endure temperatures approaching 1800°C—well beyond the melting point of many metallic materials. This heat resistance makes ceramics indispensable in environments where exposure to extreme temperatures is inevitable, such as in furnaces, aerospace components, and high-temperature manufacturing processes.

As materials heat up, they typically undergo thermal expansion, a phenomenon where their size and volume increase. Ceramic materials, however, exhibit a low coefficient of thermal expansion, often less than half that of most steels. This property is crucial in applications where dimensional stability is paramount. The low expansion rate ensures that ceramics maintain their structural integrity even when subjected to significant temperature variations. This makes them ideal for use in precision components and devices where consistent size and shape are critical.

Thermal conductivity, defining the ability of a material to transmit heat, varies among different ceramics. Advanced ceramics offer a wide range of thermal conductivity. Some materials, like silicon carbide, boast high levels of conductivity, efficiently transferring heat. In contrast, others, such as Zirconia, exhibit low thermal conductivity—approximately 1/10th that of stainless steel. This diversity in thermal conductivity allows for tailored applications based on specific heat transfer requirements.

The dynamic evolution of ceramics in medical devices

The dynamic evolution of ceramics in medical devices

The landscape of medical devices is undergoing a swift transformation with the rapid integration of ceramics into increasingly intricate products and cutting-edge techniques. In a conversation with experts in the field, Stephanie Webster, a writer for Medical Device Developments, explores the forefront of innovation in medical ceramics.

Ceramic materials, inherently inorganic and non-metallic, extend far beyond the conventional notions of pottery. The term ‘ceramic,’ derived from the Greek ‘keramos,’ meaning ‘potter’ or ‘pottery,’ encompasses a spectrum of applications across four main categories: traditional ceramics, refractories, cementitious materials, and advanced ceramics.

- Traditional Ceramics: Rooted in clays, traditional ceramics form the foundation for everyday items, ranging from bricks to cups and tiles to washbasins.

- Refractories: With the ability to withstand high temperatures and chemical assaults, refractories line furnaces for metal and glass melting and play a crucial role in firing other ceramics.

- Cementitious Materials: Integral to the construction industry, cementitious materials, based on cements and mortars, contribute significantly to structural applications.

- Advanced Ceramics: Boasting diverse engineering properties, advanced ceramics, categorized into electroceramics, engineering ceramics, and bioceramics, drive innovation in fields like electronics, energy generation, defense, and healthcare.

Within the realm of healthcare, bioceramics emerge as trailblazers, finding applications in artificial bones, joints, and dental materials. This category further divides into bioinert and bioactive ceramic materials, with the former requiring a tissue layer for separation and the latter promoting direct connections between the body and implants to enhance the healing process.

As per estimates by The Ceramics Society, the global annual ceramic market is anticipated to soar to approximately $287 billion by 2022. Notably, advanced ceramic materials are projected to be the fastest-growing segment, with the global annual medical ceramics market expected to reach a remarkable $26 billion by 2025.

In essence, the convergence of ceramic materials and medical technology paints a dynamic picture of innovation, promising groundbreaking solutions and enhancements in patient care. As ceramics continue to evolve and diversify, their influence on the medical device landscape is poised to shape the future of healthcare.

The prowess of ceramics in medical devices

The prowess of ceramics in medical devices

Ceramic materials have emerged as stalwarts in medical device applications, and their popularity across various industries can be attributed to their unparalleled performance capabilities. This robust material stands resilient against extreme stresses, high temperatures, nuclear radiation, and aggressive chemicals, making it indispensable in the medical field.

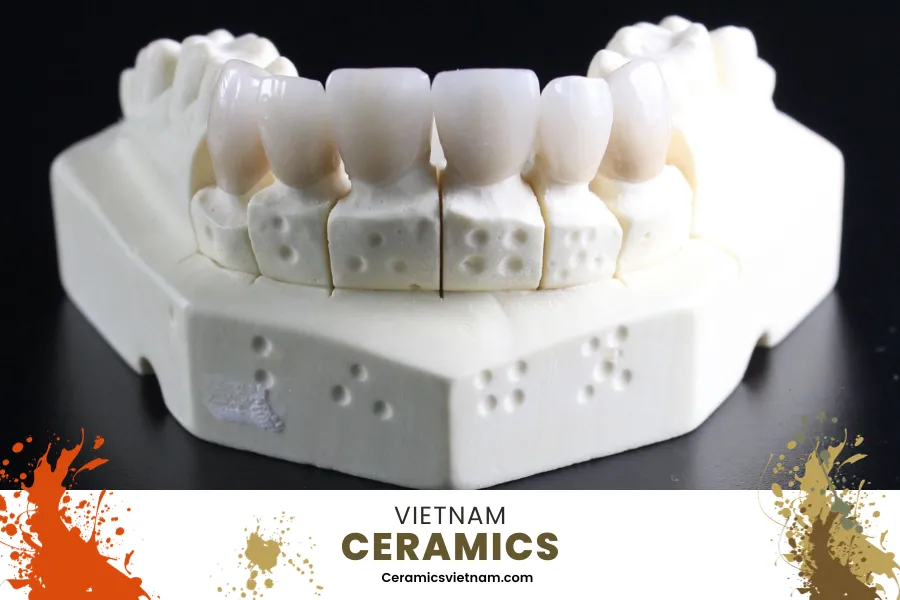

According to Professor Roger Narayan from the Joint Department of Biomedical Engineering at the University of North Carolina and North Carolina State University, ceramic materials play a crucial role in healthcare applications, particularly in hip and knee replacements, as well as dental restorations. Hip replacements, now a routine and highly successful orthopedic procedure, witness over 50% utilizing a ceramic ball and, in some cases, a ceramic cup.

Andy Weymann, Chief Medical Officer at Smith & Nephew, highlights several advantages of ceramics, making them ideal for implants. Ceramic materials, being harder than metals, exhibit superior corrosion resistance and can withstand the challenges posed by body fluids. Additionally, when combined with polyethylene or used as ceramic on ceramic, ceramics provide low-wear bearing couples, significantly reducing the risk of implant loosening and the need for revisions.

Biocompatibility is a pivotal concern in the realm of implants, and ceramics shine in this aspect. Eileen de Guire of the American Ceramic Society emphasizes the importance of ceramics in mitigating the effects of the chemically active interior of the human body. Ceramic materials not only resist corrosion but also offer tunable compositions and structural support.

Despite their already impressive properties, the evolution of ceramic materials in medical applications continues. As de Guire notes, ongoing developments aim at enhancing biocompatibility and refining device designs. Specific improvements include accommodations for anatomical differences between men and women in hip implants, increased wear resistance in ball and socket materials, and improved adhesion longevity in bone cements.

Certain ceramic materials, such as alumina, zirconia, and silicon nitride, stand out as nearly inert materials, providing wear-resistant and corrosion-resistant performance in medical and dental implants. Bioactive ceramics like hydroxyapatite and Bioglass, on the other hand, form direct bonds with bones, making them valuable for bone and dental tissue replacements.

In conclusion, the prowess of ceramic materials in medical devices is not only a testament to their current capabilities but also a glimpse into the ongoing advancements that promise even greater biocompatibility and functionality. As ceramics continue to evolve, they remain at the forefront of medical innovations, contributing to the success and longevity of implants in orthopedics and dentistry.

The drawbacks of ceramics in medical applications

The drawbacks of ceramics in medical applications

Despite the myriad advantages ceramic materials bring to the realm of medical devices, their application is not without limitations. Professor Narayan sheds light on these downsides, emphasizing the inherent brittleness of ceramics. The strength of ceramics heavily relies on flaw-free structures, making the pursuit of flawless ceramics crucial.

To overcome these limitations, nearly inert ceramic coatings can be strategically deposited onto the surface of metallic medical devices. This process imparts high hardness, wear resistance, and corrosion resistance to the devices, expanding their utility.

However, the intrinsic limitations prompt the exploration of combinations with other high-tech materials. For instance, the fusion of a titanium hip prosthesis with a ceramic head and a polyethylene acetabular cup enhances friction reduction and resistance to abrasion, while preserving the durability associated with metals.

Chief Medical Officer Andy Weymann highlights additional challenges, including limited design flexibility and comparative softness of ceramics in certain cases. Careful consideration and appropriate application are essential to harness their benefits effectively.

While ceramics have historically been associated with replacement parts like hips, knees, teeth, and bone fasteners, their evolving role extends beyond traditional implants. Eileen de Guire from the American Ceramic Society underscores the diverse applications of ceramics in medical technology, ranging from lead zirconate titanate ceramics for sensors to glass spheres delivering targeted cancer treatments.

The expanding scope of ceramic materials in medical innovation is exemplified by applications such as glass fibers aiding in wound repair, ceramic nanofibers detecting disease biomarkers in breathalyzers, and tattoo-like sensors for diabetes monitoring. Notably, advancements like bone scaffolds made of hydroxyapatite showcase how ceramics can provide mechanical support and chemical building blocks for bone growth.

Beyond the horizon of current applications, researchers are exploring groundbreaking possibilities, such as 3D-printing new body parts like kidneys, urethras, and tracheas. The tantalizing prospect of eliminating the tethering of dialysis and enhancing the quality of life for individuals with compromised body parts fuels ongoing research in the dynamic intersection of ceramic materials and medical technology.

The future of ceramics in medical advancements

The transformative role of ceramic materials in medical devices

As we peer into the future, the trajectory of ceramic materials in the medical realm promises a landscape of innovation and transformative developments. Professor Narayan anticipates a wave of new ceramics entering the market, poised to revolutionize various medical applications in the coming years. This includes more resilient hip and knee replacements, elevated-quality dental restorations, novel materials for wearable devices, and advanced materials facilitating drug delivery and bone healing.

One notable advancement in diagnostics leverages the unique atomic structure and defect chemistry of ceramics. The pioneering work of Pelagia-Irene Gouma, the Edward Orton Jr. Chair in Ceramic Engineering at Ohio State University, focuses on breathalyzers capable of detecting organic markers for serious diseases. Gouma’s research involves nanofibers of transition metal oxides, providing a substantial surface area with a defect structure that accommodates organic compounds, allowing for the specific detection of disease markers.

While the potential of ceramic materials in medical applications is vast, the highly regulated nature of the medical device industry necessitates a realistic outlook on the time frames for progress. Regulatory bodies, such as the US FDA (Food and Drug Administration), play a crucial role in keeping pace with research and development, ensuring that medical devices incorporating emerging technologies like ceramics can efficiently navigate the path to market.

Despite regulatory challenges, the evolving nature of ceramic materials in terms of biocompatibility, strength, and longevity positions them for a wide array of exciting medical applications. While ceramic materials may trace their origins back to the ancient world, their enduring potential resonates strongly, promising to extend well into the 21st century and beyond. As research and innovation pave the way, ceramic materials stand as a beacon of progress, heralding a future where they play an increasingly pivotal role in advancing medical technologies.

In conclusion, the integration of ceramic materials into the realm of medical devices marks a significant stride in the pursuit of enhanced performance and longevity. While their advantages, including hardness, corrosion resistance, and biocompatibility, underscore their prowess, acknowledging limitations such as brittleness is crucial. The future promises a surge in innovative implants, diagnostic tools, and materials, heralding a transformative era in medical technology. As ceramics continue to evolve, their enduring potential, deeply rooted in ancient origins, is set to play a pivotal role in shaping the future landscape of healthcare, offering groundbreaking solutions for generations to come.

Read more

Leave a reply